Equipment Productivity Monitoring System

|

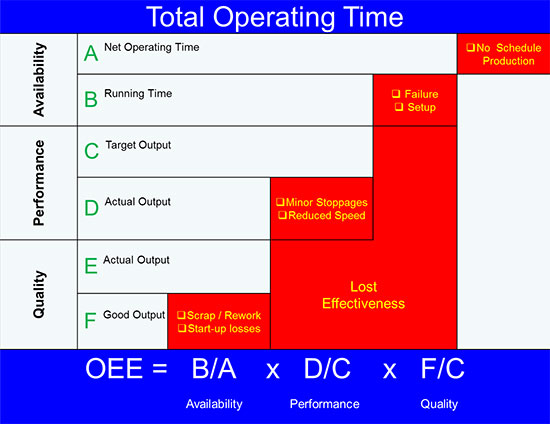

What is OEE OEE stands for Overall Equipment Efficiency and is a key measurement in a lean manufacturing implementation. It was developed by Seiichi Nakajima in the 1960's as a hierarchy of metrics based on Harrington Emerson's philosophy on labour efficiency. It evaluates and indicates the efficiency of the manufacturing floor. Today OEE is the Standard Measurement Index used by leading manufacturers worldwide.Measuring and Tracking the Overall Equipment Effectiveness is crucial in your efforts to reduce equipment and process related wastages. The High Level formula for OEE is: |

|

OEE = Availability x Performance x Quality

|

|

Availability: Actual vs Planned Production Time

|

|

|

Performance

|

|

|

Quality

|

|

|